Depending on your project, it is sometimes vital to get a precise edge and use an effective tool that doesn’t stick and has increased longevity, such as the Diamond wire saw from www.well-dws.com

What Are Diamond Wire Saws?

In principle, diamond wire saws are saws that use a cable or metal wire for cutting. They are similar to reciprocating saws or band saws. They are characterized by their cutting wires covered in diamonds. There are hand-powered ones suitable for cutting trees and industrial electric-powered ones. Wire saws are identified as endless (continuous) or reciprocating (oscillating). The wire is sometimes called a blade. Rather than use saw teeth to cut, instead, they use abrasion. Diamond content may sometimes be utilized as an abrasive, depending on the use. The wire may be fitted with one or more interwoven strands. The single-strand saw type can be roughened to achieve the abrasive effect. Abrasive agents can be connected to the cable, or the cable can be threaded with diamond-infused spacers and beads. Wire saws are usually lubricated and cooled using oil and water. Contact a specialist manufacturer online, such as www.well-dws.com, to purchase or seek detailed information about this tool.

Design

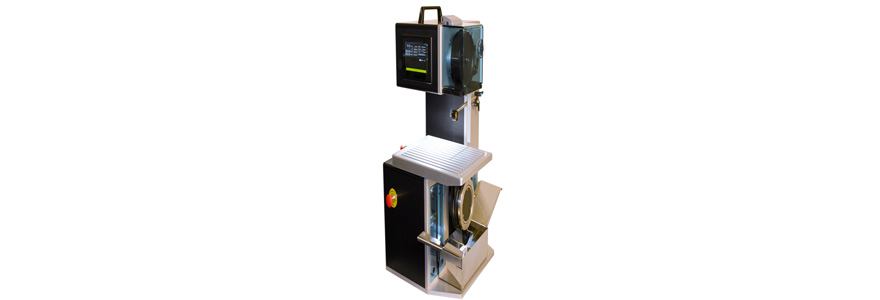

The cutting tool is a stainless-steel wire. In this wire, authentic synthetic diamonds have been squeezed (no boron nitride). The patented method of covering provides an optimum potential for cutting and extended wire life. The wire is wrapped around a drum that’s been mounted on a reciprocal generator. The wire length varies according to the scale of the saw types. Most diamond saws are gravitational or use a weight mechanism to obtain and sustain a steady feed rate. Furthermore, the speed of the diamond saw is constantly controlled; hence, it varies in speed.

Functionality

Diamond saws provide a trim that leaves almost every material with burr-free, smooth, and sharp surfaces. They allow sawing in either direction, facilitating complex 2D contours. A low clamping force allows the diamond wire to be fitted quickly. Minimal waste and dust are achieved by a narrow cut. It never jams and remains free. The wire’s multiple bending capability ensures that the chip space is cleaned better after each step that occurs with rigid tools. The diamond saw is constructed in a manner that makes it particularly appropriate for delicate materials as no chipping occurs due to the closely directed saw wire enabling precision cutting.

Advantages

The motor-driven feed rate is used to ensure accuracy in following a pre-programmed contour, making it suitable for sawing graphite contours. An optimum outcome is obtained during the operation in conjunction with the automatic tool adjustment radius. In laboratories, they are used for cutting delicate substrates, crystals, and other materials. The technology can also be used to dismantle sophisticated scientific systems.

In Conclusion

This tool is ideal for use in multiple setups depending on the outcome you require. It will ensure you have minimal wastage of materials and simultaneously give you precise cuts. The maintenance is minimal, requiring only water and oil for cooling and lubrication. It is designed in a way to ensure longevity. For more details on this tool, contact a specialist manufacturer online, like www.well-dws.com. With their range of expertise and years of experience, you’ll get access to all the information you require. You can also purchase it from them combined with a range of other effective tools at competitive prices.